Back Riveting Bucking Bar

Back Riveting Bucking Bar Description

Material selection and processing

We use powder metallurgy technology: high-purity tungsten powder - molding (compression molding or injection molding) - vacuum sintering densification process - forging and rolling - precision grinding - surface polishing - comprehensive quality control.

Characteristics

Good high-temperature performance

It has a high melting point and still has high strength and creep resistance in extremely high temperature environments, making it suitable for riveting operations in high temperature environments.

Good chemical stability

It has strong corrosion resistance to acid, alkali and salt solutions at room temperature, and is resistant to corrosion by molten metals. Its oxidation resistance at high temperatures is better than that of most metals.

Strong mechanical properties

High strength, high hardness, excellent impact and fatigue resistance, extremely strong wear resistance and long service life.

High riveting quality

It is suitable for repeated riveting, has small thermal deformation, can ensure the dimensional accuracy of the workpiece, and meets the requirements of different riveting processes.

Application

Bucking Rivets are a standardized connection element. Bucking Bar is generally used to transfer the mechanical force of riveting equipment (such as riveting guns and presses) to rivets or workpieces, push the rivets to deform, ensure the accurate position of rivets during the riveting process, and ensure the quality of riveted joints.

- Aerospace: Rivet Bucking Bar is used for riveting of aircraft engine combustion chamber components, turbine blades and frames, and the connection of spacecraft structural parts. It can withstand high temperatures and high stress loads, ensure the reliability of connections, and ensure the safe operation of aerospace vehicles.

- Precision Machinery Manufacturing: In the manufacture of some precision machinery with extremely high precision requirements, such as optical instruments and CNC machine tools, Bucking Bar Tool can be used for the connection of key components. It can maintain high precision during the riveting process, avoid loose connections or dimensional deviations caused by thermal deformation or stress relaxation, thereby ensuring the performance and stability of precision machinery.

- Electronics and Semiconductors: For micro-riveting of micro components such as thermocouples and pressure sensors, tungsten riveting bars can achieve high-precision connections to ensure the accuracy and quality of chip packaging.

- Special material connection: Bucking Tool For Rivets is used for riveting refractory metals such as molybdenum, tantalum, niobium, and other dissimilar materials such as metals and ceramics, and composite materials. It can buffer the interface stress caused by the difference in thermal expansion coefficients between different materials and ensure the normal use of the materials.

Back Riveting Bucking Bar Dimension

|

Material |

W-Ni-Fe & W-Ni-Cu |

|

Purity |

W:89%-99% |

|

Diameter |

1-10mm |

|

Length |

10-200mm |

|

Hardness |

HRA85-90 |

|

Density |

18.3-19.0g/cm3 |

|

Tensile strength |

1000 - 3000MPa |

|

Surface |

Finish turning, Milling, Grinding |

|

Standard |

ASTM B777,MIL-T-21014 |

|

Certification |

ISO 9001 |

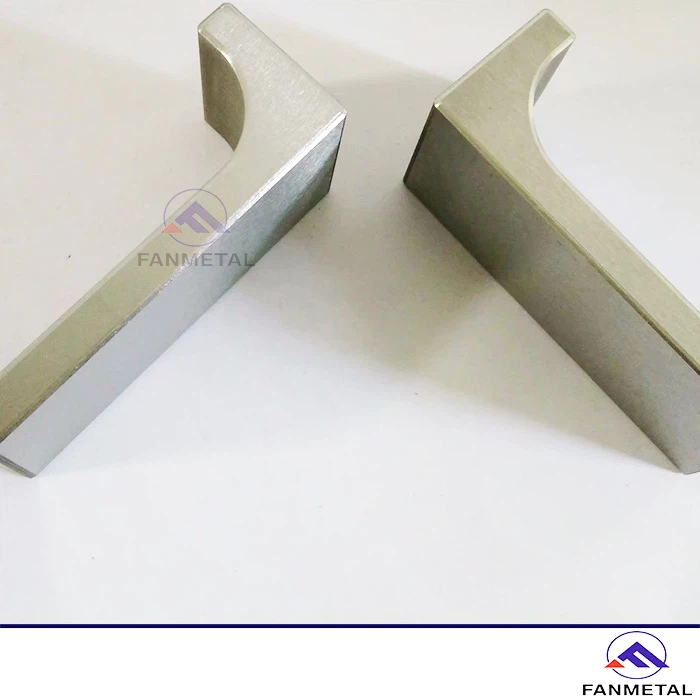

Back Riveting Bucking Bar Pictures

Product Qualification

FAQ

Q: Are you a manufacturer or a trading company?

A: We are a manufacturer with professional technology and several years of production experience, and can provide customers with various high-quality products.

Q: Do you accept customed?

A: Yes, we accept. We will design and produce products according to the specific information you provide, and also assure you that we will try our best to come up with the best solution to provide you with high quality products.

Q: How to order our products?

A: Customers can first send us an email to tell us their ordering requirements, and we will provide a product catalog. After determining that a certain type of product is needed, we will reconfirm with the customer the order quantity, price and whether customized service of product specifications is required. If necessary, customers can provide drawings directly or put forward their own requirements. We will provide samples here and put them into production after consensus is reached. The delivery period is then determined based on the quantity or the number of days for custom processing. If the delivery time changes due to some factors, we will inform customers in advance.

Q: Do you provide free samples? How long can it be delivered?

A: Yes, we can provide free samples and deliver within 7-20 days.

Hot Tags: back riveting bucking bar, suppliers, manufacturers, factory, customized, wholesale, price, quotation, for sale, Tungsten Alloys for Oil and Gas Industries, Tungsten Rhenium Alloy, Tungsten Counter Balance Weights, Astm B777 Tungsten Heavy Alloy Rod, High Density Tungsten Counterweight, Tungsten Alloy Counter Weight

Send Inquiry