Titanium MIG Wire

Titanium MIG Wire Description

Material selection and processing

High-purity titanium alloy TC4 ingots are selected and processed through multiple cold drawing processes, annealing, surface treatment and strict quality control. Precision cold processing and full anti-pollution technology are required during the production process to ensure the chemical composition uniformity, dimensional accuracy and welding performance of the wire.

Characteristics

- High strength, strong fatigue resistance, wear resistance, and long service life.

- Good arc stability, high welding efficiency, and good weld quality.

- Strong corrosion resistance, high surface finish, and high dimensional accuracy.

- Can match base materials of different strength levels, with good processing performance.

Application

The commonly used grade of Titanium MIG Wire is titanium alloy TC4, which is mainly used in the aerospace field for fuselage structure and frame welding, engine component welding, aircraft titanium alloy component crack repair and other processing. It can not only provide high-strength connections to ensure that these components remain stable under complex stress conditions, prevent deformation, fracture and other problems, and ensure the safe flight of aerospace vehicles, but also achieve lightweight and optimized layout of the structure with lightweight design, thereby improving the space utilization and performance of aerospace vehicles.

| Aerospace | Titanium alloy fuselage frame and engine nacelle welding | High-strength welds, automated mass production |

| Medical Devices | Titanium alloy artificial joints, orthopedic implant welding | Low pollution, corrosion resistance, and meeting biocompatibility requirements |

| Chemical Engineering and Marine Engineering | Titanium pipelines (such as TA2), seawater desalination equipment welding | Corrosion-resistant, long-life welds |

| Automobile and rail transportation | Titanium alloy chassis components, high-speed train lightweight structure welding | Small welding deformation and excellent fatigue resistance |

| Sports Equipment | Titanium alloy bicycle frame, diving cylinder welding | Balance of aesthetic shape, light weight and high strength |

Titanium MIG Wire Dimension

|

Grade |

Ti-6Al-4V |

|

Purity |

Ti≥90% |

|

Diameter |

0.1mm-20mm |

| Tolerance range | ±0.01-±0.03mm |

|

Length |

500-3000mm |

|

Density |

4.51g/cm3 |

|

Melting point |

1668-1680℃ |

|

Surface |

Polished, Bright |

|

Shape |

Coil |

|

Standard |

ASTM B863/GB/T 3623-2019 |

|

Certification |

ISO 9001 |

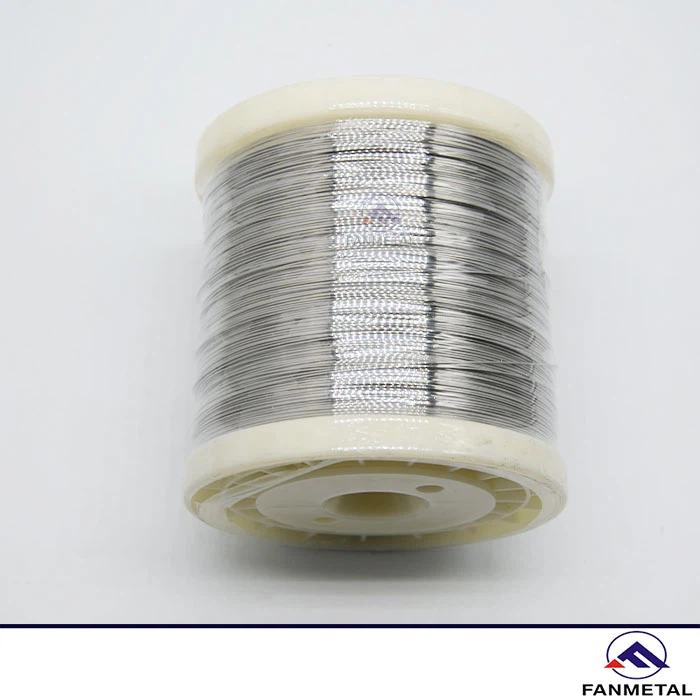

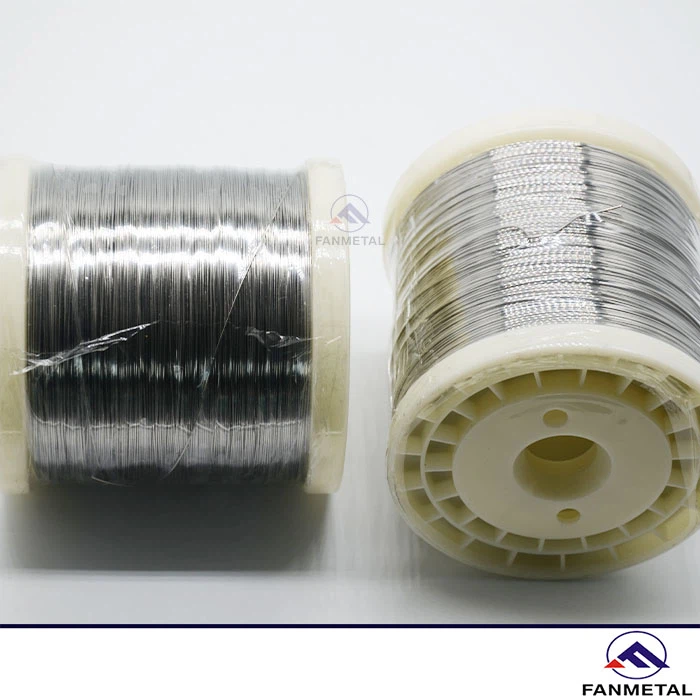

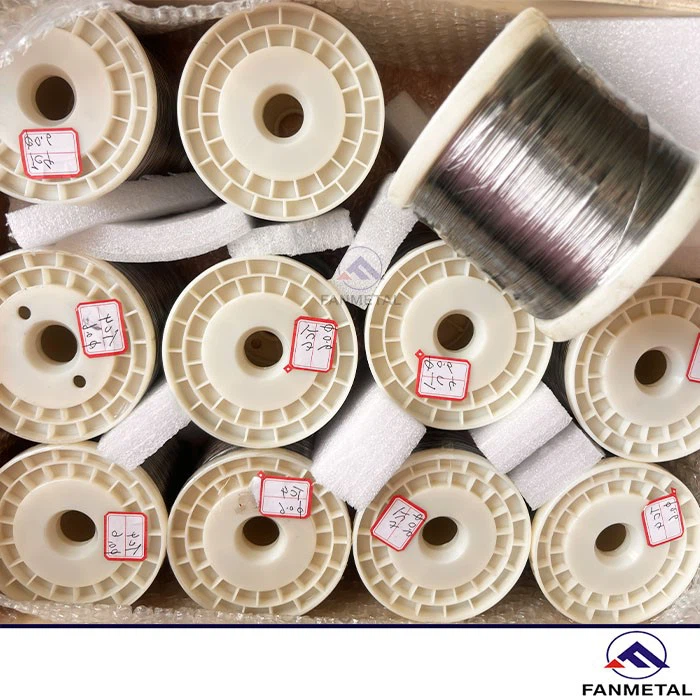

Titanium MIG Wire Pictures

Product Qualification

PACKING

Hot Tags: titanium mig wire, suppliers, manufacturers, factory, customized, wholesale, price, quotation, for sale, Ti 6Al 4V Titanium Sheet, Titanium Round Bar, Industrial Titanium Foil, Gr5 Titanium Sheets, Industrial Titanium Forging, Titanium Sheet

Send Inquiry